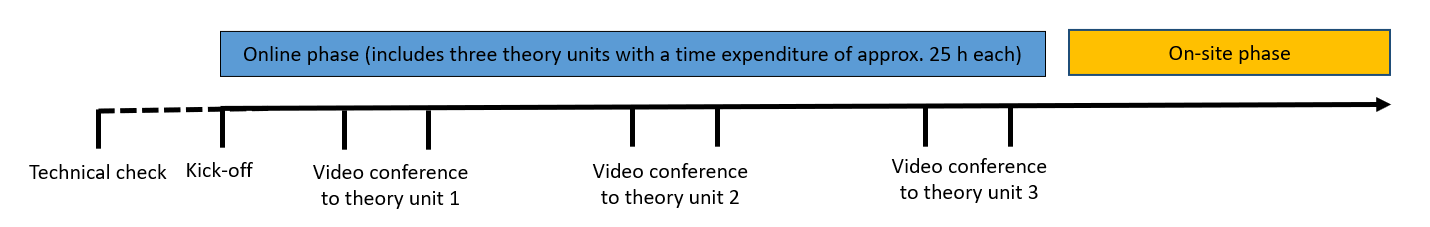

A technique check is offered before the start of the course to check that the hardware and software are working properly. All you need to participate in the course is browser access.

The course itself starts with a kick-off video conference for all participants (see figure 1). This will allow you to get to know the other participants and the trainers. In addition, the learning platform and its functions are explained.

The subsequent online phase comprises three theory units, each with a duration of approx. 25 hours. The detailed course contents can be viewed here: Adhesive specialist course contents (PDF).

For each of these three online units, you have the opportunity to view the learning content via our learning platform or download and work through it offline. The content is conveyed through short videos, presentations and animations. To support your learning success, flashcards, interactive learning checks and exercises are available for you to work on in small groups or alone.

In addition, you will meet with the trainers and your course group at mandatory online video conferences (see in figure 1) to talk about previously defined course topics to be worked through, to discuss questions and to further consolidate the knowledge you have acquired. However, should anything be unclear or in need of explanation beforehand or »in between«, the trainers are of course also available for questions.

Following the online phase, the five-day on-site phase including the practical, written and oral examinations takes place at Fraunhofer IFAM. Here, further topics are presented so that all the contents of the DVS®/EWF Adhesive Bonding Specialist course are covered. Likewise, all practical exercises are now carried out and linked to the theory. You will be optimally prepared for the upcoming examinations through repetition units. After successfully passing the exams, you will receive the internationally recognised DVS®/EWF certificates.

Online phase (e-learning in three units)

- Interactive learning on computer, tablet, smartphone or offline

- Regular video conferences between course group and trainers

- Support through e.g. virtual flashcards and interactive learning checks

- Learning without time pressure: individual and independent of location

On-site phase

- Receipt of the course documents for the entire European Adhesive Specialist course

- Refreshing, intensifying and completing the theory part

- Practical exercises and exam preparation

- Taking the practical and theoretical exams (written/oral)