One week course teaches how to avoid errors when manufacturing and using FRP materials

DIN 35255 defines standardised quality requirements for fibre-reinforced plastic processes in companies. The requirements for the qualification of composite specialists are now clearly defined for the first time.

The FRP Manufacturer is the right choice for composite personnel (CP). This proof of qualification of specific knowledge is a prerequisite for the executive level to ensure the quality of fibre-reinforced plastics and applies across all industries. The FRP Manufacturer should work in particular where the fibre composite plastic processes for the production of FRP components are carried out professionally and independently in accordance with professional work instructions.

Qualified personnel are required to use Fiber reinforced plastics (FRPs) professionally and to fully exploit its innovative potential. These experts must know and understand the special features of the material, as well as the interplay between material and production process - because not all FRPs are the same.

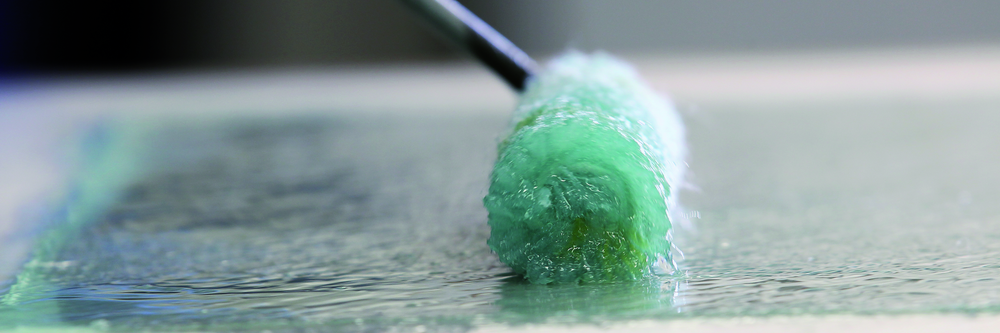

In practice, the choice of each individual component and also the manufacturing process has a great influence on the properties of the resulting material and thus also on the properties of the component. The Fraunhofer IFAM therefore offers the one-week course "FRP Manufacturer" in which a basic understanding of FRP is imparted, manual manufacturing processes are learned in practice and the recognition of faults in the material is practised.