Dr. Zhang, what was the motivation behind your decision to offer professional training on composite material in cooperation with the Fraunhofer IFAM?

We have seen a dramatic increase in production of composite materials in China within the last years due to a growing interest for lightweight structures in railway, automotive, airplane manufacturer or even home appliance industry. Therefore there is a high demand for professional training in these industries. Engineers and technicians are facing new challenges for example for surface treatment, suitable joining methods for composites and other materials, repair processes and how to prepare requirement lists to suppliers.

In the last years we have gained a lot of experience in professional training in adhesive bonding technology in cooperation with Fraunhofer IFAM and now we want to transfer this business model to composite technology. There are differences between adhesive bonding and composite technology regarding target customer. Nevertheless, the target industries are the same and we are sure that we can approach our target customer by most of our current channels.

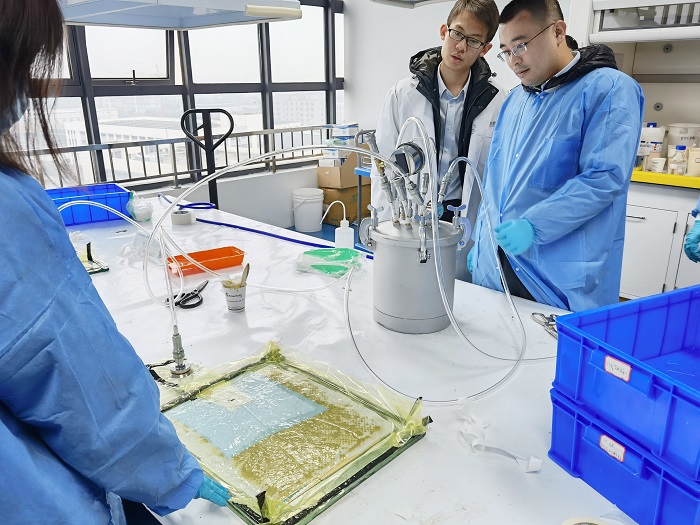

We started to set up our professional training team more than two years before the first course. We hired high quality trainers with good educational background and working experiences in the composite field and trained them at Fraunhofer IFAM. Thanks for the excellent cooperation between Fraunhofer IFAM and YIFA, we did a lot of preparation work before the course, including translation, interpretation, hands-on practice and rehearsal, which made our first pilot course very successful.

Mr. Kelch, where do you see the potential in offering professional training courses in cooperation with Yifa New Materials?

In recent decades, we have observed that the production of many components made of composite materials such as rotor blades for wind turbines or railway components has shifted from the European region to the Asian region. These products are sold worldwide and need to fulfil the high quality demands of different markets. In contrast to many other materials, composite materials have a complex structure and their properties depend on a lot of different factors. Therefore quality assurance is a necessity for the successful and safe application these materials. An essential component of the quality assurance process is the professional workforce qualification. Yifa New Materials and it’s partner Yifa Bonding have gained a lot of experience in high quality workforce qualification as a competent partner of Fraunhofer IFAM in adhesive bonding technology within the last years and we are sure, that we can adapt this system to workforce qualification in the field of composite materials.

Dr. Zhang, what are the next steps for a successful implementation of composite training in the Asian market?

Within the feedback from our first course, most of our participants valued our composite course as “practical and valuable for day-to-day work”, especially for those without systematical knowledge of composites. They learned the composition of composites, the function of matrix and fiber, the peculiarities and characteristics of different materisl, what type of factors influence the material properties and a lot more.

Due to the high demand for composite training courses in Asia, additional one-week courses on the topics of composite production and repair are to be held in the future. In China, the high speed train and tram were put into operation more than 10 years ago. Many vehicles now come to the maintenance period with demanding of composite repair.

Additionally there is a o lot of innovation in the vehicles materials, many companies start the design and manufacture of pure CFRP vehicles, which has high requests on composite training. With the big support from Fraunhofer IFAM, we are approaching more industries that are using composite materials such as aerospace, shipbuilding, wind etc. I believe more and more industries will be attracted to this training course just like adhesive bonding technology.

Moreover, there are requests on composite technical research projects and we have the intention to cooperate with the Fraunhofer IFAM professional team to provide joint technical support to China companies.

In the coming months we will introduce further cooperation partners of Fraunhofer IFAM. Stay in touch with us via our website, our newsletter, or the social networks (Xing/ LinkedIn)!